How It All Works, Making Designer Toy from Start to Finish.

1). You need have an idea first. Sometimes like a drawing – a character or kaiju essentially, with background history is very important. This Can help make it special and vintage.For example the ‘Casper Pup’.

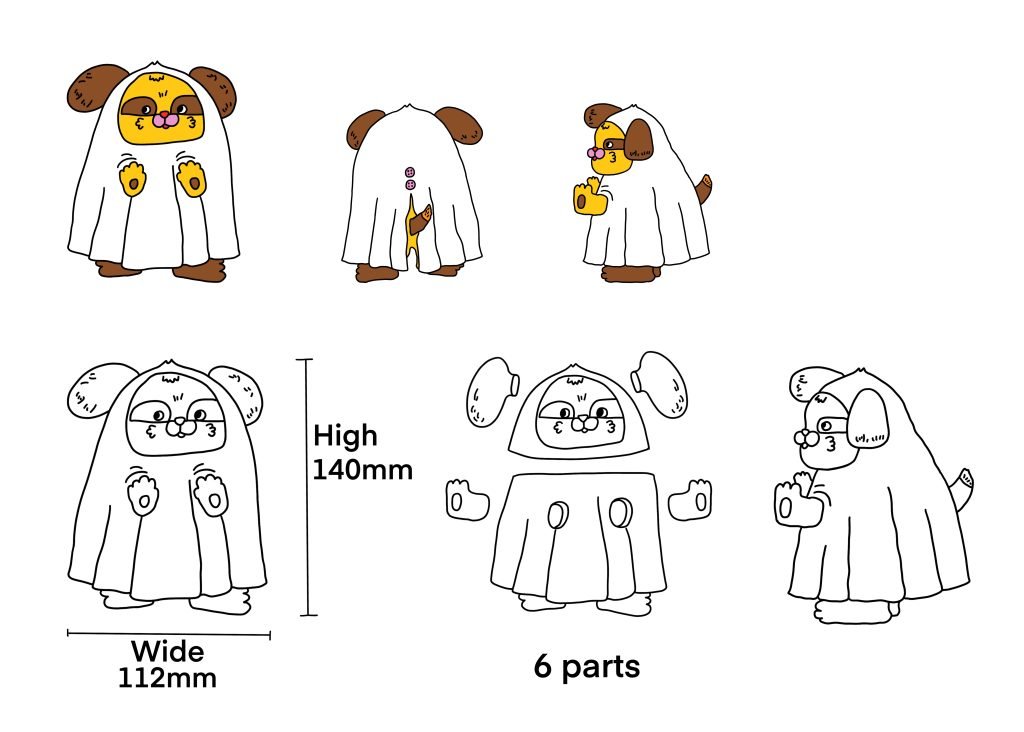

Design Drawing

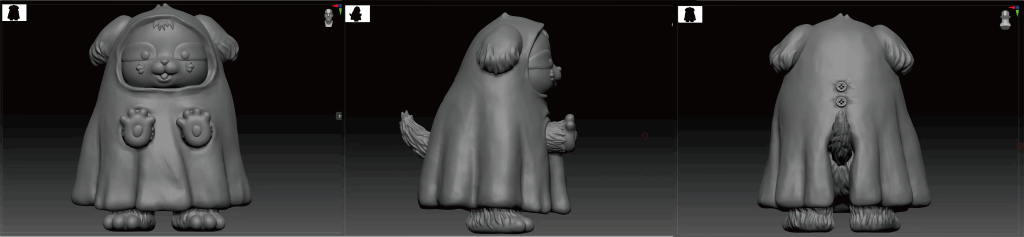

2). A prototype or sculpt is needed. Traditionally this is made in clay. If you have 3D file (STL or OBJ format is better) that will be helpful as well. We can help do clay sample and 3D modeling. Once get the files we will disassemble the design into individual parts based on movable part you need. When all approved,the grey and well sanded sample will be printed.Here’s part of the ‘Casper Pup’ – using 3D modeling.

3D Modeling

3D Printing

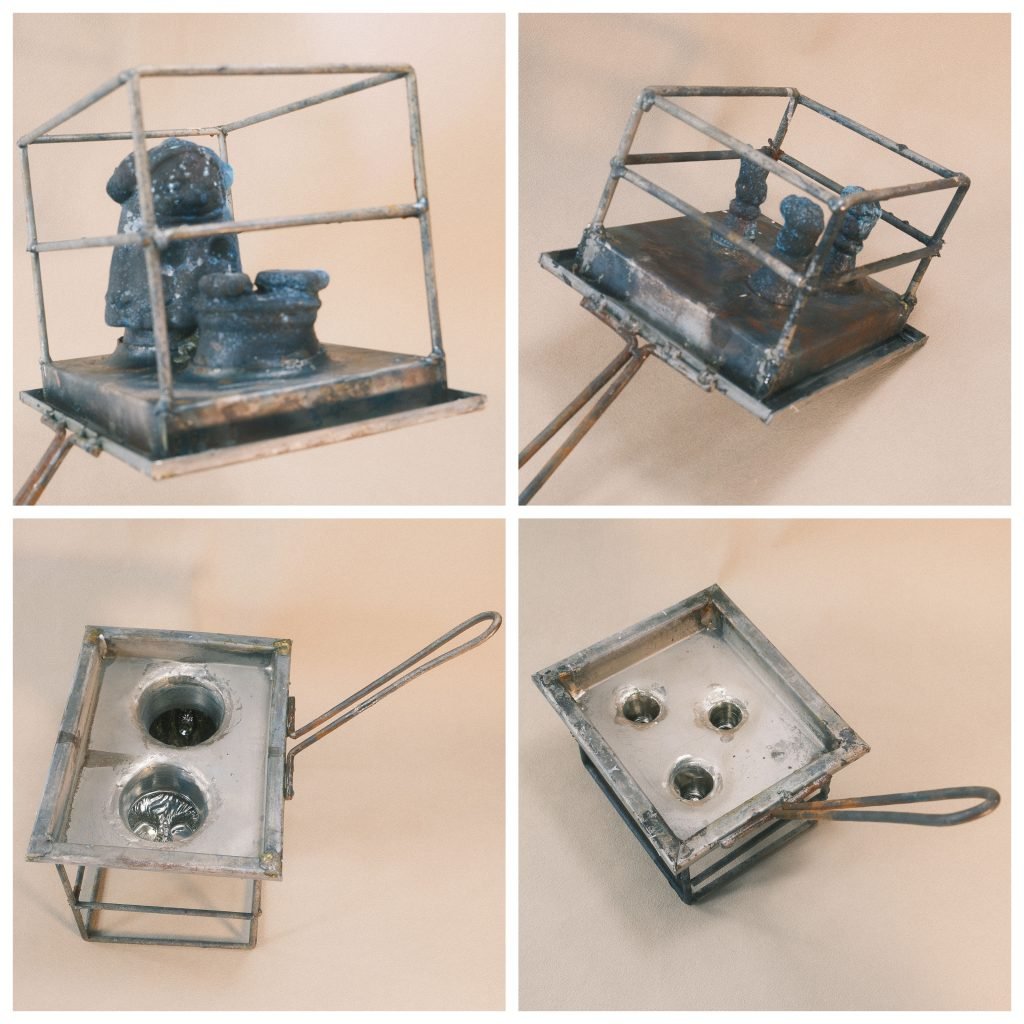

3).This step a wax mold will be made using silicone, The rough wax prototype is smoothed and made nice and shiny – like the one ‘Casper Pup’ shown bellow.Also if you have logo need to be engraved, AI file will be needed. The finish on this piece will be the finish on your final vinyl casts, so this step is very important. The details will be kept and also very important part for copper mold, this may take around 7-12 days to do the surface finishing.

Wax Mold

Wax Finishing

4).After wax mold done, it will be moved to metal mould making.First electro-coating the wax proto with copper, then melting the wax out from inside the mold,finally step Welding the copper mold to a steel frame for use in the factory, and waiting for the mould test pull.

Wax Mushroom Head

Electro Coating

Frame Welding

5).When the mould is finished, it will be moved to ‘Vinyl Test Pulls’, which are usually done in stock colors (flesh, white, black for example).In this part we can check the structure if that fit well.After this Mould Test Sample(MTS) finished, next step will be waiting for mass production.

6). After all this confirmed, the following step is the actual manufacturing of the different colored vinyl product.Generally Pantone number will be needed or if you have any pics that for color ref. this will be helpful.

A Brife Process of Making a SOFUBI

Drops of rain could be heard hitting

“Getting up early all the time”, he thought, “it makes you stupid. “Oh, God”, he thought, “what a strenuous career it is that I’ve chosen! Travelling day in and day out. Doing business like this takes much more effort than doing your own business at home, and on top of that there’s the curse of travelling, worries about making train connections, bad and irregular food, contact with different people all the time so that you can never get to know anyone or become friendly with them.

Best selling Products

-

Heavy Desk Light$349.00

Heavy Desk Light$349.00 -

Nans PF:80 Outdoor Ceiling Lamp$4,900.00

Nans PF:80 Outdoor Ceiling Lamp$4,900.00 -

Bloom Pendant$349.00

Bloom Pendant$349.00

Leave a Reply